Whether you own a commercial or residential property, all of your concrete surfaces should be protected year-round. Concrete sealers are one of the most effective methods of doing so. Continue reading to review some common questions and answers about sealing concrete pavements, and who to trust for commercial and industrial paving work in the Indy areas.

FAQS About Concrete Sealing

Why Seal Concrete?

There are several benefits to sealing concrete surfaces and pavements. The primary advantage of using a concrete sealer is enhanced longevity. Your concrete surface will stand up better against natural wear and tear (wind, rain, snow, ice, traffic, etc.) and similar pavement damages (chemical spills, dirt, oil, etc.), and for a longer period of time.

Not only does this protect your investment since it abates unnecessary or premature concrete repair, but it also improves and sustains visual appeal. When it comes to property value, curb appeal is important, and the condition of your concrete can make all the difference when it comes to remortgaging or selling.

Do I Have to Seal New Concrete Pavement?

After pouring and laying new concrete pavement, applying a sealer is one of the most important preventive maintenance methods you can take to extend the look and life of your results. Although you don’t have to do anything with your concrete pavement, it is wise to use concrete sealers for the sake of protecting your investment, ensuring safety, and abating liability. Without a concrete sealer, your newly-laid concrete will be subjected to cracks and potholes within a period of weeks. A concrete sealer will provide instant protection against anything that wants to damage your concrete.

Do I Need to Seal Concrete Pavement More Than Once?

It is important to reseal your concrete surfaces and pavements on a regular basis to ensure optimal protection. The regularity in which you reapply your concrete sealers will depend on various factors, including the current condition of your concrete, the type of sealer used, the level of craftsmanship during installation, and much more. However, the general rule of thumb is to reseal concrete pavements every 3 to 10 years, or more frequently for regions that experience extreme climates, such as extreme cold or extreme heat.

What Kind Of Concrete Sealers Are Available?

There are various types of concrete sealers and sealing products available over the counter, and several others used by professional concrete paving companies. All types of concrete sealers are either solvent-based or water-based. Within these categories, the most common types of concrete sealers include polyurethane, acrylic resin, penetrating resin, and epoxy products.

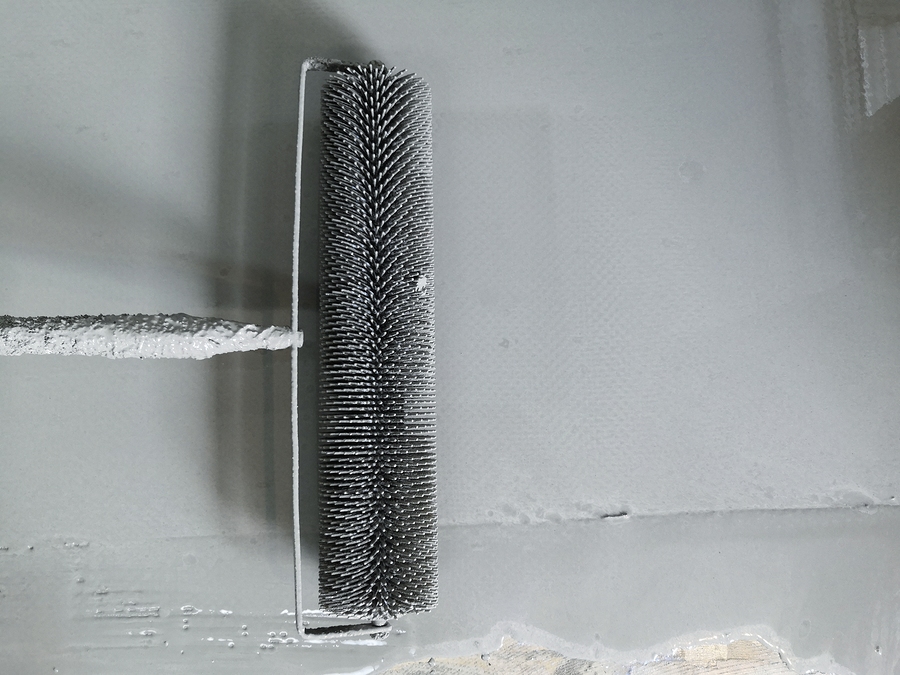

These sealers are designed to block moisture, oil, water, and other penetrable contaminants for the purpose of maintaining structural and aesthetic integrity. Solvent-based concrete sealers are applied by either sprayers or rollers, while water-based concrete sealers are applied using rollers.

Are you looking for professional concrete ceiling and reinforcing services for your commercial or industrial property in Indiana? Contact ACI Asphalt and Concrete at 317-549-1833 for reputable and trusted pavement sealcoating and concrete repair services in Indianapolis, Indiana.

You Should Also Read:

The Difference Between Crack Sealing and Crack Filling

Is it Better to Apply a Thicker Layer of Seal Coat?

Factors to Consider When Choosing a Sealcoat