Maintaining a well-marked and organized parking lot is more than just a detail; it’s a vital component of property management that affects safety, aesthetics, and compliance with local and federal regulations. Whether you manage a retail store, office building, or apartment complex, ensuring that your parking lot is clearly marked is crucial for a positive impression and safe experience.

But how do you know when it’s time to re-stripe your parking lot? This blog will guide you through the signs, benefits, and cost considerations of re-striping while answering common questions to help you make an informed decision.

Signs Your Parking Lot Needs Re-Striping

Fading or worn-out parking lot lines not only detract from your property’s appearance but can also lead to safety hazards and non-compliance with regulations. Here are key signs it’s time for a fresh coat of paint on your parking lot lines:

- Faded or Dull Lines: If your parking lines, arrows, or other markings are no longer visible from a distance, it’s time to consider re-striping. Clear markings help drivers easily identify parking spots and traffic flow.

- Peeling Paint: Flaky or peeling paint is not only unsightly but also a sign that your parking lot maintenance needs attention.

- Confusing Layout: Over time, lines may completely fade, leading to drivers parking at improper angles or creating their own patterns, disrupting the traffic flow.

- New Regulations: Local codes and ADA guidelines can change. If your parking lot has not been updated recently, it’s worth reassessing compliance requirements.

When Is the Right Time to Re-Stripe?

How often you should re-stripe your parking lot depends on various factors, including traffic volume, weather conditions, and paint quality. Here are general recommendations to guide you:

- Annually for High-Traffic Lots: Parking lots with significant traffic or heavy vehicles should typically be re-striped once a year.

- Every Two Years for Moderate Use: Lots with moderate daily usage might only need re-striping once every two years.

- After Sealcoating: Any sealcoating job requires re-striping immediately afterward to restore the markings.

- Seasonal Considerations: Spring and summer are ideal times for striping, as dry and warm weather ensures proper paint application and faster drying times.

Regularly inspecting your parking lot for wear and tear can help you stay ahead of the need for re-striping.

Enhancing Safety and Compliance

Parking lot striping is not just about aesthetics; it plays a crucial role in enhancing safety and ensuring regulatory compliance. Here’s how:

- Improves Traffic Flow: Properly marked lanes, arrows, and stop lines prevent confusion and accidents.

- Ensures Pedestrian Safety: Crosswalks and designated walkways guide pedestrians safely through your lot, reducing the risk of accidents.

- Maintains ADA Compliance: Federal ADA guidelines require accessible parking spaces with designated signage and markings. Non-compliance can lead to fines and legal issues.

- Fire Lane Visibility: Clear fire lane markings ensure emergency vehicle access, meeting local code enforcement requirements.

By maintaining a clearly marked and compliant parking lot, you not only protect your visitors but also safeguard your business from liability.

Understanding the Costs of Re-Striping

Planning for parking lot striping involves understanding the costs. Here’s a breakdown of common pricing factors:

Per Parking Space

- Single Space: $8 – $20

- Double Space: $16 – $40

Linear Feet

- $0.08–$0.25 per linear foot for comprehensive re-striping projects.

Additional Costs

- Stencils for ADA-compliant markings or custom layouts.

- Traffic control measures during the striping process.

- Layout adjustments for improved traffic flow or updated compliance requirements.

Factors such as project size, paint type (e.g., water-based vs. oil-based), and regional pricing can also influence the total cost. Investing in high-quality paint and professional striping ensures longevity, saving money in the long run.

Contact Us for Professional Line Striping

Common Mistakes to Avoid When Re-Striping

To maximize the lifespan and effectiveness of your parking lot striping, steer clear of these common mistakes:

- Skipping Surface Preparation: Failing to clean and prepare the pavement leads to poor paint adhesion and premature wear.

- Overlooking ADA Requirements: Non-compliance with ADA guidelines can result in fines and require costly rework.

- Using Low-Quality Paint: Cheaper paint may save upfront costs but will fade or peel quicker, requiring frequent reapplication.

- Ignoring Traffic Flow Patterns: An improperly planned layout can cause congestion and safety hazards.

- Imprecise Measurements: Incorrect spacing or proportions can waste valuable lot space and leave it looking unorganized.

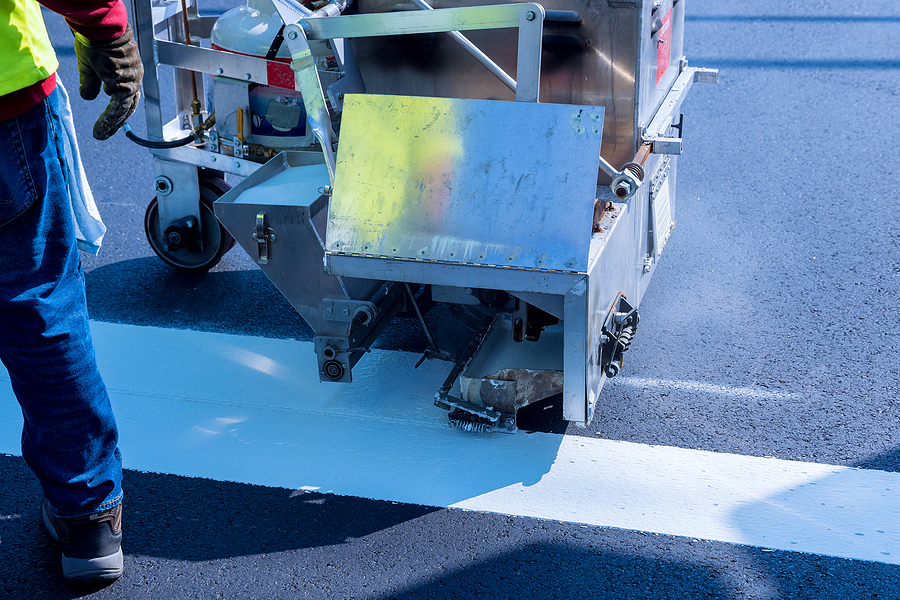

Always enlist professional parking lot striping services to avoid common pitfalls such as uneven lines, improper spacing, or fading paint. Professionals use the right equipment and expertise to ensure a durable, high-quality result that enhances safety, organization, and the overall appearance of your parking area.

Key Questions About Parking Lot Striping

Still have questions? Here are answers to some FAQs property managers often ask:

How often should I re-stripe my parking lot?

Most lots need re-striping every 1–2 years, but high-traffic areas may require more frequent updates.

What type of paint is best for parking lot striping?

Water-based paints are environmentally friendly and ideal for warmer climates, while oil-based paints offer more durability in colder regions.

How does striping improve safety?

Clear markings reduce confusion, facilitate traffic flow, and guide pedestrians, preventing accidents and ensuring a safe environment.

How long does parking lot striping take?

Most small to medium-sized lots can be striped in just a few hours, minimizing downtime for your business.

How can I prepare my parking lot for striping?

Cleaning the surface and addressing any cracks or potholes ensures better adhesion and a smoother finish.

Maximize the Benefits of Timely Re-Striping

Re-striping your parking lot is a simple yet impactful step toward enhancing safety, ensuring compliance, and improving curb appeal. Investing in your parking lot’s appearance and functionality demonstrates a commitment to your property’s visitors while protecting your business from avoidable fines or liabilities.

Is your parking lot due for a refresh? Schedule your service with ACI Asphalt and Concrete and enjoy the benefits of a well-maintained and clearly marked parking lot. Our team of experts will ensure quality striping that lasts.

Related Post: Reasons to Choose Reflective Paint for Line Striping and Road Markings