In today’s competitive business landscape, every detail matters – and the state of your premises is no exception. A well-maintained, aesthetically pleasing, and safe parking lot can make a significant positive impression on your clients, employees, and visitors. That’s where professional asphalt services come into play. By opting for commercial asphalt repair and sealcoating, you ensure a multitude of benefits that go beyond mere cosmetics.

Read on to discover the importance of these services, the credentials you should be looking for in a provider, and why asphalt sealcoating should be your go-to choice for maintaining your business premises.

The Importance of Professional Asphalt Services

Asphalt is the most popular choice for commercial parking lots, driveways, and roadways due to its durability and cost-efficiency. However, just like any other material exposed to weather conditions and heavy traffic, it requires regular maintenance to preserve its quality and extend its lifespan. Neglecting this can result in costly repairs or even full replacement in the long run. That’s why investing in professional asphalt services is crucial for your business – they help you keep your premises safe, visually appealing, and well-maintained, all while reducing the risk of potential legal consequences.

Look for These Credentials in a Commercial Asphalt Company

Not all asphalt service providers are created equal. To ensure quality workmanship and exceptional results, make sure to look for the following credentials when choosing a commercial asphalt paving company:

License and insurance: A reputable commercial paving company should be licensed and insured. This ensures that they have met all necessary requirements and can provide you with high-quality service.

Experience and expertise: Look for companies that have been in the business for several years and have a team of experienced professionals. They are more likely to provide you with top-notch service and handle any unexpected issues that may arise.

Quality materials: The quality of the asphalt used is crucial for the longevity and durability of your pavement. Make sure to choose a company that uses high-quality materials.

Customer reviews: Take the time to read reviews from previous clients to get an idea of their experiences with the company. A reputable business will have positive reviews and happy customers.

Top Reasons to Choose Asphalt Sealcoating

While there are different types of pavement maintenance options available, asphalt sealcoating stands out as the most effective one. Here’s why:

Protects against weather damage: Sealcoating acts as a protective barrier against harsh weather conditions such as rain, snow, UV rays, and more. This prevents water from seeping into the pavement, causing cracks and potholes.

Increases longevity: Regular sealcoating can significantly extend the lifespan of your asphalt pavement, saving you money on costly repairs or replacements in the long run.

Enhances appearance: A fresh coat of sealcoat makes your pavement look brand new, boosting the curb appeal of your business premises.

Cost-effective: Sealcoating is a cost-effective option for maintaining your pavement. It’s much more affordable than repairs or replacement and can significantly increase the value of your property.

Other Important Asphalt Paving Services Offered

Aside from sealcoating, professional asphalt companies offer a wide range of other services to keep your pavement in top condition. These include:

ADA compliancy: A reputable business will ensure that your pavement meets all necessary ADA (Americans with Disabilities Act) regulations, providing safe and accessible parking for all.

Pothole repair: Potholes not only pose a safety hazard but can also damage vehicles. Professional asphalt companies use advanced techniques and high-quality materials to repair potholes effectively.

Vegetation control: Overgrown vegetation can cause cracks and damage to your pavement. Professional asphalt companies offer vegetation control services to keep your pavement clear and safe.

Drainage solutions: Poor drainage can lead to water pooling on your pavement, causing damage over time. Professional asphalt companies provide effective drainage solutions to prevent this issue.

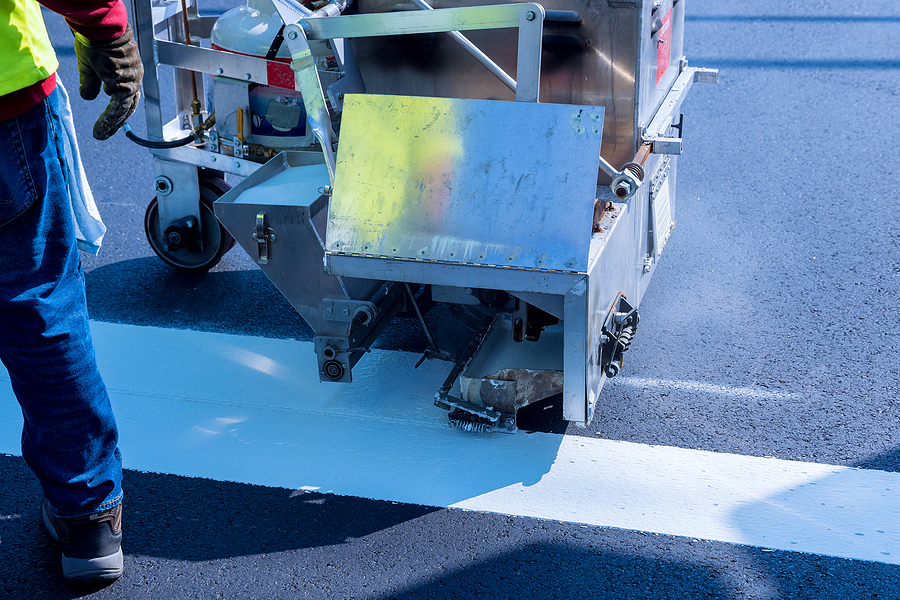

Pavement markings: Clear and visible pavement markings are crucial for the safety and organization of your parking lot. Professional asphalt companies offer expert pavement marking services to ensure your pavement is ADA compliant and easy to navigate.

Final Thoughts

Don’t overlook the importance of professional asphalt services for your business. Choosing a reputable company that offers high-quality workmanship, uses top-notch materials, and provides a wide range of services can help you maintain an impressive, safe, and visually appealing premises that will leave a lasting positive impression on your clients and visitors. So, make sure to prioritize regular asphalt maintenance to reap the numerous benefits it offers for your business.

Since you have now learned about the many benefits of professional asphalt services, why wait? Contact ACI Asphalt and Concrete at 317-549-1833 and give your business premises the care and attention they deserve! We offer asphalt and concrete work, including sealcoating services and pothole repair.

Related Posts:

Commercial Asphalt Paving: Your Questions Answered

Key Considerations When Opting for Commercial Asphalt Paving

Commercial Asphalt Paving: Your Questions Answered