When it comes time to choose between two of the most popular and constructive paving materials for your property, understanding their differences, advantages, and disadvantages is a wise step toward making the best investment decision. Continue reading to learn what makes asphalt difference from concrete, as well as some of the most common pros and cons of each paving material.

Asphalt and Concrete

Asphalt, also known as bitumen, is a dark bituminous pitch made from a combination of binder (usually refined liquid petroleum), filler, and aggregates like sand, gravel, stones, and grit. It is essentially crushed rock that has been heated and then cured into a hard, flat finish. Once cured, it is sealed with a seal coat, making it a non-permeable pavement that retains flexibility in order to withstand changing weather conditions and more.

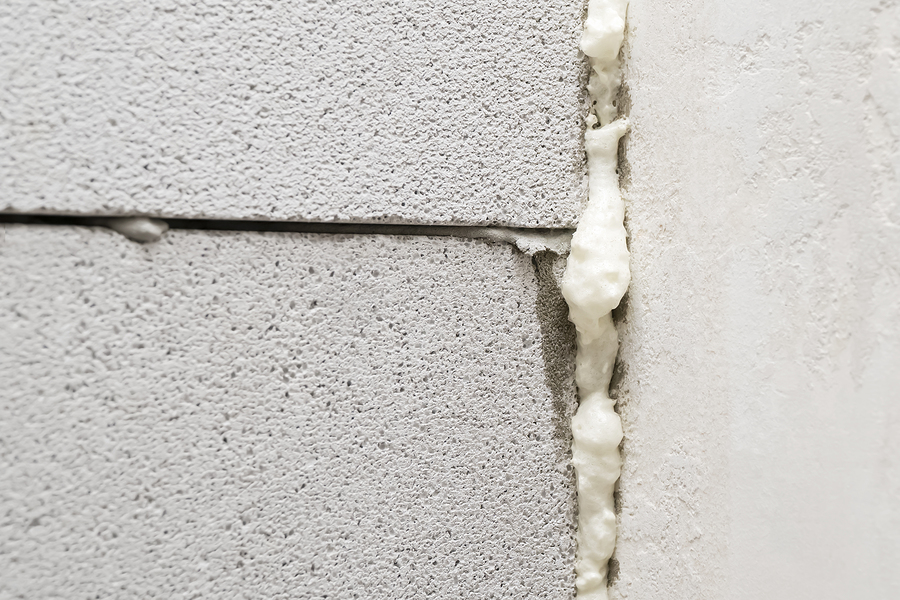

Concrete is a man-made material prepared from cement, as well as certain aggregates like sand and gravel. It is a porous pavement, making it highly vulnerable to water permeation. After water enters the pores of the concrete, it will freeze and thaw with the changing seasons, which will cause cracks and other defects to surface in the following years.

Pros and Cons of Both

Take a look at some of the most common advantages and disadvantages of asphalt and concrete. This will give you an idea of what to expect, and perhaps help you make a wise buying decision. If you still have questions and concerns, your best course of action would be to talk to a licensed, bonded, and insured paving company for answers and advice you can trust.

Pros and Cons of Asphalt

Asphalt is easy to repair, cheaper to purchase, quicker to install (which also means cheaper labor costs) and is much better for the environment. It is widely noted for its sleek, smooth finishes and uniform appearances. On the other hand, asphalt has a lower lifespan than concrete. It is also less durable, requires ongoing maintenance, and can even soften in extreme heat conditions.

Pros and Cons of Concrete

Concrete is highly versatile and can be finished in an infinite array of colors, stains, scores, styles, and designs. It can even be made to imitate higher end materials, like brick, tile, and cobblestone. Compared to asphalt, it is more durable, can withstand extreme heat, and lasts much longer. However, concrete is more expensive to install and more difficult to repair. It is also prone to cracking in seasonal temperature fluctuations (freeze thaw cycles).

Do you have questions about your commercial paving needs? Contact ACI Asphalt and Concrete at 317-549-1833 for licensed, bonded, and insured pavement installation and repair in Indianapolis, Indiana.

Related Posts:

Top 3 Reasons Why is Asphalt More Popular Than Concrete

A Quick Comparison of Warm Mix Asphalt and Hot Mix Asphalt

Is it Possible to Lay Asphalt on Top of Concrete?