Before concrete polishing innovation, concrete was drab, matte, and almost always grey. But now that we have products, equipment, and knowledge to polish concrete, these surfaces have never looked so amazing. In fact, concrete is becoming more and more popular for residential properties too. This is because concrete polishing gives home and property owners options in color, shade, grade, texture, style, and more! Not only does polished concrete offer a variety of looks, it is easy to clean and maintenance too!

Continue reading to learn more about polishing concrete and the benefits it offers residential and commercial properties.

Polished Concrete

Polished concrete is treated concrete that looks glossy and retains a constant and brilliant shine. Before, concrete was solely used for constructing foundations in homes and buildings; but now with the new polishing technology, concrete can serve multiple purposes and be used as an alternative flooring option.

Instead of traditional carpeting, laminate, hardwood, linoleum, or tile flooring, polished concrete is a new option that might better provide the look and feel you are looking for. This is because its patterns and colors can be customized just the way you like! In fact, polished concrete can imitate other flooring types, like tile or stone. You can even install it for outdoor or patio purposes too!

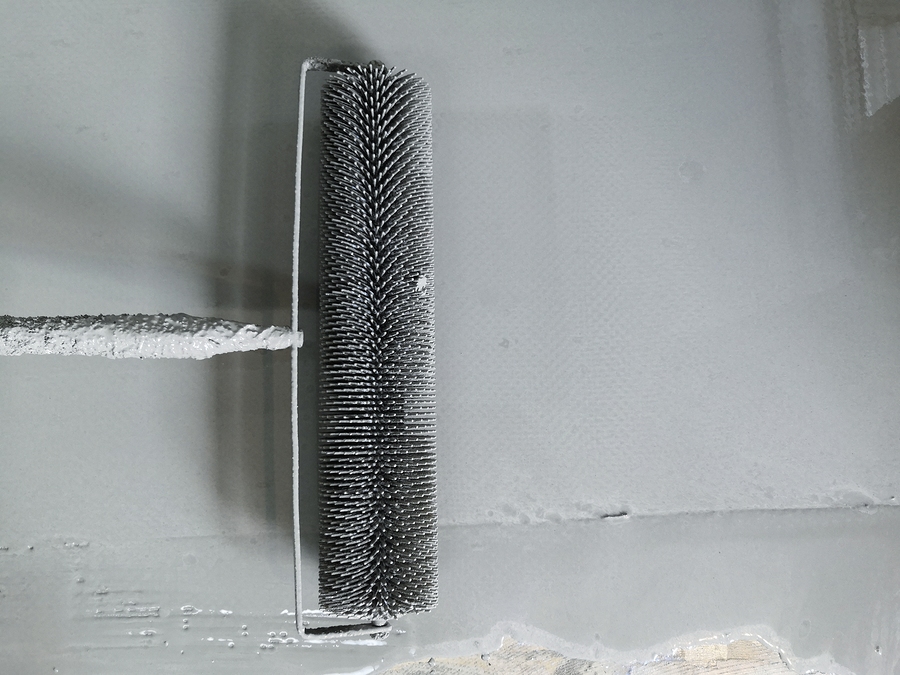

Polishing and grinding machines are used to achieve these effects for concrete. It is very similar to sanding wood, but instead, it is concrete that is being buffed and shined. And with acid-staining technology, customizing the colors, patterns, and effects is easy! So long as new concrete has had at least 28 days to manicure and mature, it is ready for polishing.

If you wish to polish existing concrete, it must first be thoroughly washed, rinsed, and dried. Dirt, grease stains, and other surface imperfections and contaminants must be removed for optimal results. If existing concrete is uneven or very porous, it has to first be resurfaced, and then properly cleaned.

Top Benefits of Concrete Polishing:

☑ Non-Slip Flooring

☑ Dirt-Resistant

☑ Easy to Clean and Maintenance

☑ DIY Products and Options

☑ No Need for Seal Coating and Waxing

☑ Can Be Used for Countertops Too!

Once polished concrete is lain, dried, and completely finished, owners can enjoy less maintenance and easy cleaning. A damp mop and dry broom are all you need to clean and maintain this floor type. Outsource a professional concrete repair service for any damages that occur after. They can also provide concrete polishing services.

Commercial Concrete Paving and Repair in Indianapolis

Call ACI Asphalt and Concrete at 317-549-1833 for commercial concrete pavement service in Indianapolis and its surrounding areas. Our licensed and qualified paving contractors provide a wide range of asphalt and concrete pavement repair and installation services at the most competitive prices in town, including crack filling, overlays, resurfacing, and sealcoating. Request a free estimate, today!