We walk on it, drive on it, appreciate its appeal, but seldom actually know what it’s made of. We are talking about asphalt pavements, of course! Conventional asphalt is comprised of course aggregate, stone, gravel, fine aggregate, sand, and petroleum-based asphalt cement. All of these constituents are melted down to form the black, bituminous material we know as asphalt. Also referred to as bitumen, asphalt mix can be prepared in a number of ways, but the two most common asphalt mixes used in the industry are warm mix and hot mix asphalt.

Continue below to review a quick comparison of warm mix asphalt and hot mix asphalt and move forward with the knowledge you need to make the right paving decision for project.

Hot Mix Versus Cold Mix

Hot Mix Asphalt (HMA)

Hot mix asphalt is the most popular and widely-used asphalt paving material in the country. Manufactured at temperatures ranging from 300 to 350 degrees Fahrenheit, you can see where it gets its name. It is flexible, making it more resistant to premature damages like cracking. It is also weather resistant, especially effective at repelling water. Because of its beneficial properties, hot mix asphalt is the top material used to pave highways, interstates, and roadways.

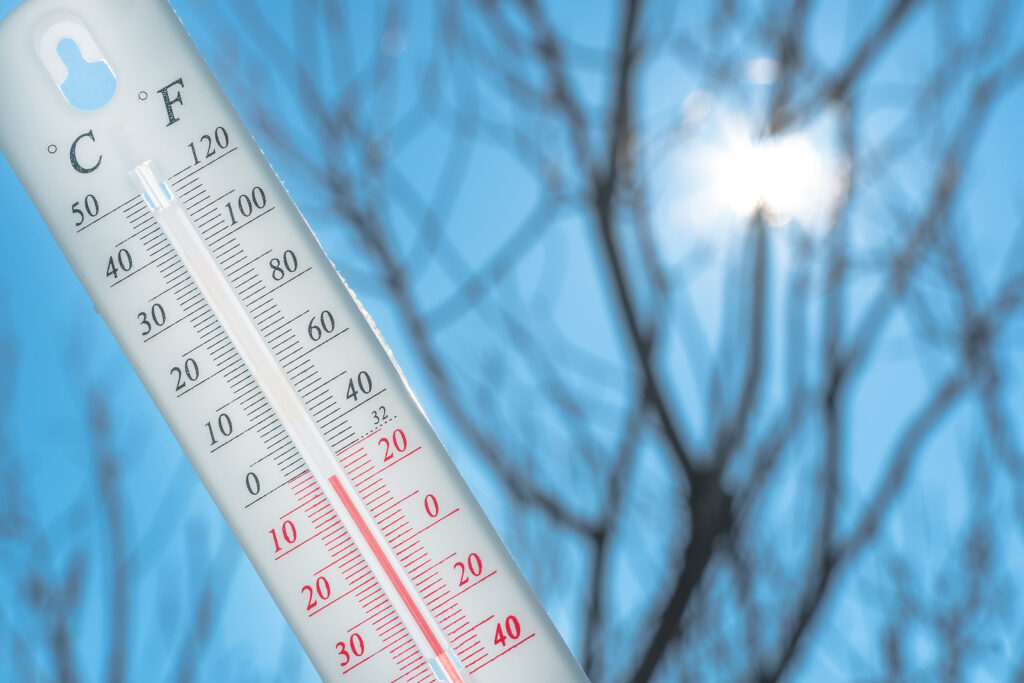

There are three different grades of HMA: dense-graded, stone matrix, and open grade. Since hot mix asphalt cools rapidly, it must be laid in certain weather conditions. Ideally, the outdoor temperature should be at least 40 degrees Fahrenheit, and the weather should be dry and ambient.

Warm Mix Asphalt (WMA)

Warm mix asphalt (WMA) is not used as much as hot mix asphalt. Only about 30 percent of paving jobs are done using warm mix asphalt. Warm mix asphalt is produced at much lower temperatures in comparison to HMA, usually between 200 and 250 degrees Fahrenheit. Warm asphalt mix can still deliver high performing results at lower temperatures because of its manufacturing process. It is made with additional binding materials like wax, emulsions, and zeolites, which also make the mix easier to work with.

Furthermore, WMA is Eco-friendly because it uses less fossil fuels and resources, and generates less dust, fumes, and smoke. Opposite of hot mix asphalt, warm mix does not cool as quickly. But this is an advantage, as it can withstand longer shipping distances and be used outside of the usual road construction seasons.

Are you looking for professional commercial asphalt paving in the Central Indiana region? Contact ACI Asphalt and Concrete at 317-549-1833 for Indianapolis Indiana asphalt paving and sealcoating services at the most competitive rates in the central parts of the state. We serve commercial, industrial, and municipal clients.

Related Posts:

How to Cure Cold Patch Asphalt

Common Asphalt Concrete Mixture Formulations

The Best Temperatures For Paving Asphalt