Whether indoors or outdoors, polished concrete has become a fantastic substitute for expensive, hard-to-maintain flooring. It has a beautiful finish that is easy to create. Not only is polished concrete cheap, easy to implement, and stunningly beautiful; it is simple to maintain and clean. To polish concrete flooring, a polishing machine that uses discs made of shattered diamonds is swiped along a floor, similar to sanding wood. It is a fantastic and easy way to make the best of concrete flooring. It is also a cheap alternative to carpeting, tile, linoleum, and hardwood.

Continue reading to learn how to care for polished concrete flooring and who to call for professional advice or assistance in your town.

Regular Maintenance for Polished Concrete

To simply clean and maintenance polished concrete on a daily basis, a few strategies need to be carried out every day. These strategies first start with mats, runners, and additional types of floor coverings. In high traffic areas, such as entry ways or hallways that lead to communal areas (i.e. restrooms, kitchens, etc.), floor mats are helpful. They reduce the negative effects of repeated foot-traffic by collecting dirt, moisture, and mud in its fibers rather than letting these permeate the floor. They also reduce color fading, stains, and general wear and tear.

Another daily method to maintaining polished concrete includes light sweeping with a soft-bristled broom. Using an industrial-strength or heavy-duty broom can cause scratches on the surface of your flooring. Be sure to use a soft broom for delicate sweeping and dusting. Also, it is important to clean spills immediately. Never allow anything sticky or stain-able to sit on polished concrete. This can jeopardize the aesthetic qualities of the floor. Another recommendation is to dry mop every day or to purchase an auto-floor machine that dusts on the hour, every hour.

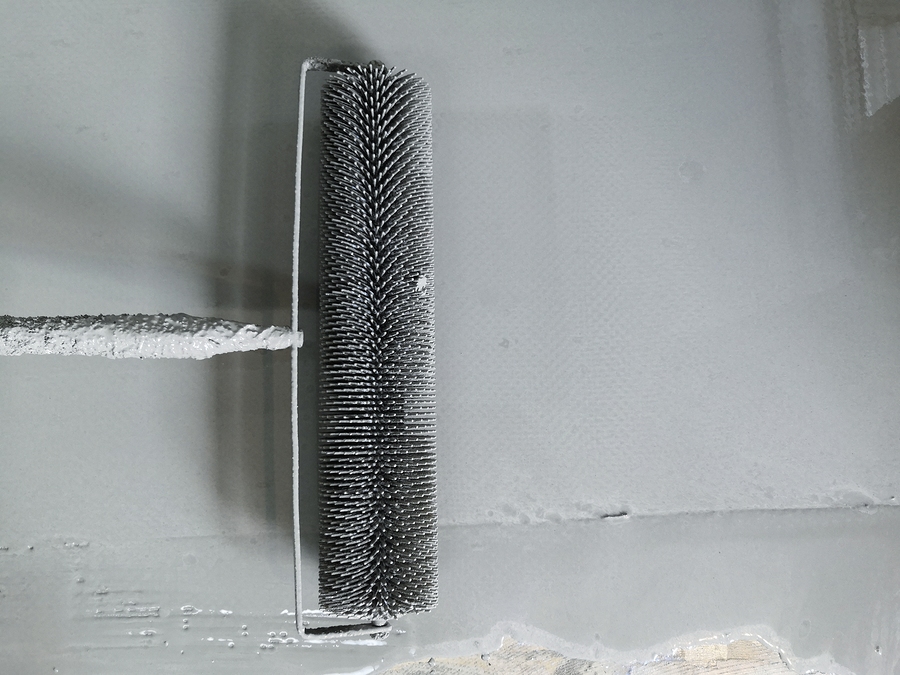

These routine maintenance strategies serve as an excellent guide to caring for polished concrete. On the other hand, this type of flooring requires more than just cleaning; they require the use of application-specific tools and effective chemistry for a longer lasting shine and stronger durability. This means mastering mechanical and chemical maintenance as well. Using diamond-plated pads to buff the surface of polished concrete floors is the mechanical aspect; while using industry-appropriate cleaners and conditioners to sanitize. It is highly recommended to consult a professional and licensed commercial concrete company for more specific instructions regarding polished concrete care.

Indianapolis Commercial Concrete Contractors

Call ACI Asphalt and Concrete at 317-549-1833 for concrete repair and maintenance in Indianapolis, Indiana. Our licensed road construction contractors provide a wide range of asphalt and concrete work for commercial and industrial properties, including inspections, installation, replacement, repair, and more. We also offer free estimates and consultations, flexible scheduling, references upon request, and more. Best of all, our work is backed by our 100% Satisfaction Guarantee, so you can rest assure that your investment is sound. Request a free quote, today.